Additive Manufacturing has reached a turning point. In the meantime, it has become a disruptive technology whose capabilities and price points, especially in the area of development projects, have long since become competitive with “classical” production methods. While the moment and magnitude of impact varies with the nature of the product and production processes, it is time for every manufacturer and developer to recognize and understand the chances and opportunities of Additive Manufacturing.

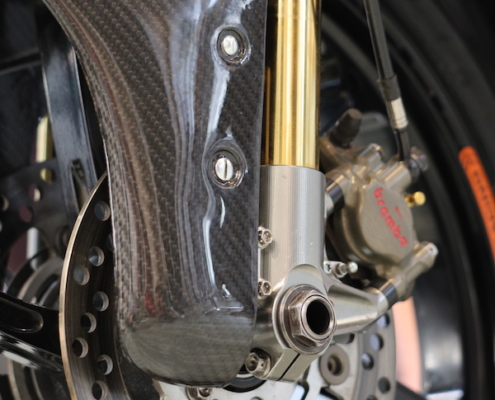

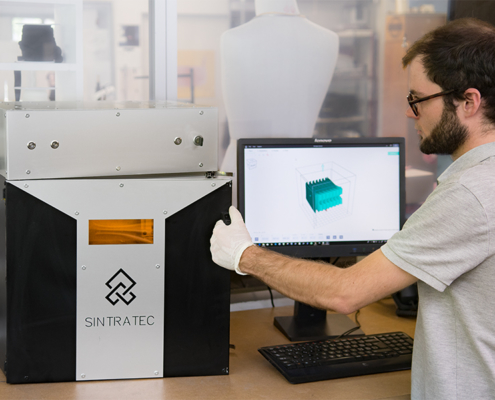

Radiate Engineering has been working on various projects for quite some time, in which additive manufacturing is becoming increasingly important. Whether it’s developing an innovative orthosis or designing a rechargeable battery box for a transport drone (as shown in the pictures below), mechanical and design components in the internal composite lab are always developed using additive manufacturing and some are fiber reinforced plastics combined.

Timothy Habermacher, Managing Director at Radiate Engineering, comments: “At Radiate, Additive Manufacturing has become an established production technology for various industries and customers. Especially when it comes to highly loaded and functional prototypes, we use Additive Manufacturing in combination with fiber-reinforced plastics. The combination makes it possible to produce economic prototypes in order to generate user feedback as quickly as possible.

ethmotoracing.com

ethmotoracing.com

Cmas Lab

Cmas Lab