Radiate Engineering & Design proudly unveils the all-new Capital SL full-carbon wheelset developed exclusively for our client, Scott Sports SA.

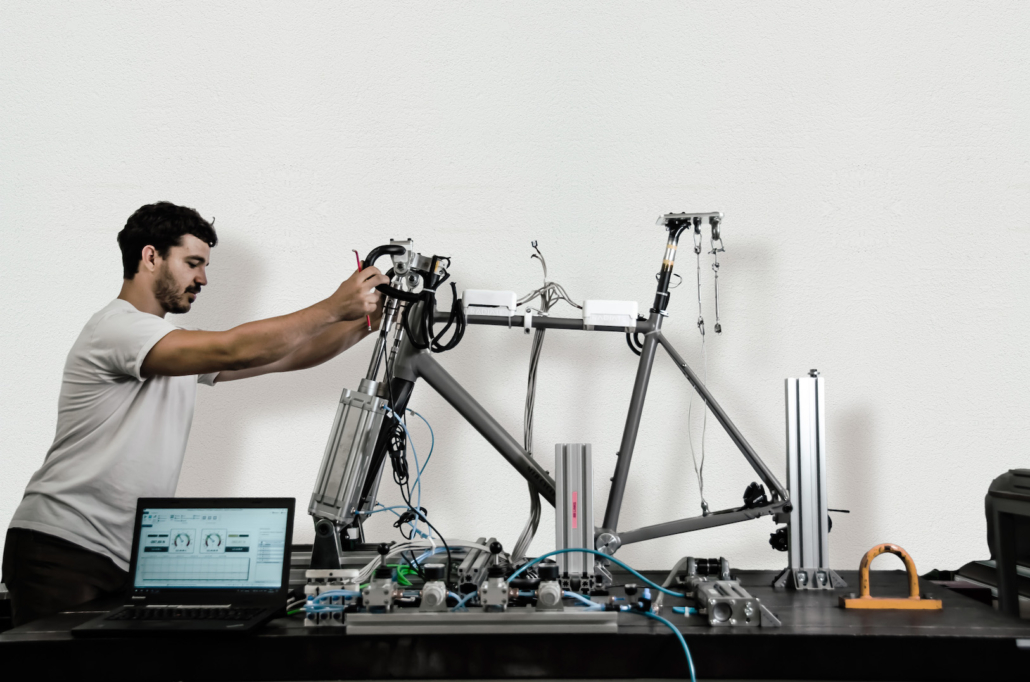

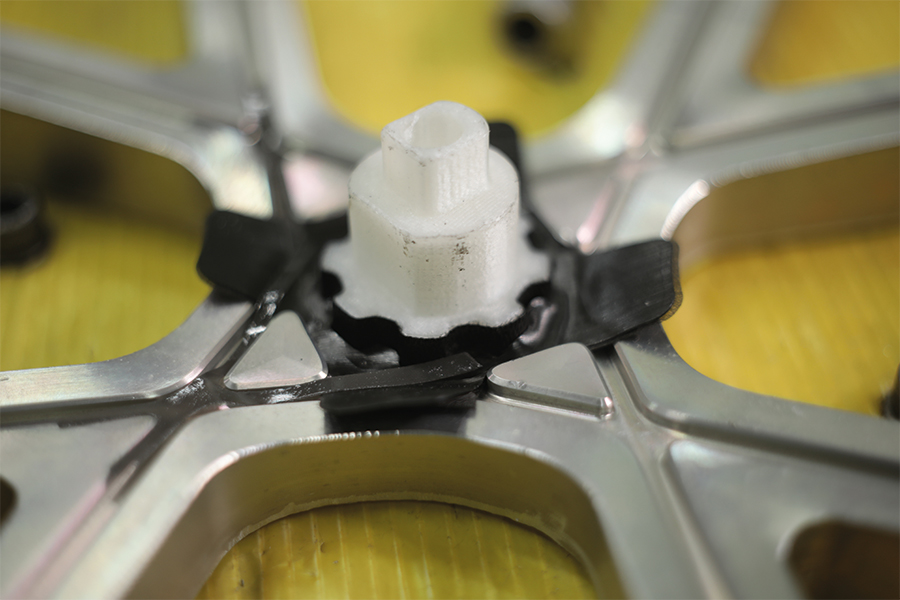

Representing a breakthrough in aerodynamic design and composite technology, the Capital SL wheelset embodies a comprehensive “System For Speed” approach, where every component has been meticulously engineered to maximize aerodynamic performance and deliver an unparalleled riding experience.

Designed to redefine speed and agility, the Capital SL wheelset combines cutting-edge technology, lightweight construction, and aerodynamic superiority. With a monocoque carbon design, these wheels offer a remarkable balance of strength, responsiveness, and reduced weight, tipping the scales at a mere 1170g. Whether conquering roads or gravel terrains, the Capital SL wheelset propels riders into the future of cycling.

“We are thrilled and immensely proud that Scott Sports SA introduces the Capital SL wheelset to riders worldwide,” says CEO Timothy Habermacher, CEO of Radiate Engineering & Design. “This revolutionary wheelset represents the pinnacle of our engineering and design expertise, delivering unmatched performance and setting new standards in speed and agility. We are excited to see how these wheels empower riders to push their boundaries and experience the thrill of riding.”

Check out more about the Engineering and Design behind the new Capital SL in the video and the image gallery.