Cost- and time efficient design finalization and prototype production for Positrigo AG

The technology from Positrigo AG offers precision medicine and makes functional imaging accessible for people worldwide. Radiate Engineering & Design developed and produced prototypes of a headrest for the NeuroLF seat, an ultra-compact brain Positron Emission Tomography system.

The collaboration with Positrigo included the following work packages:

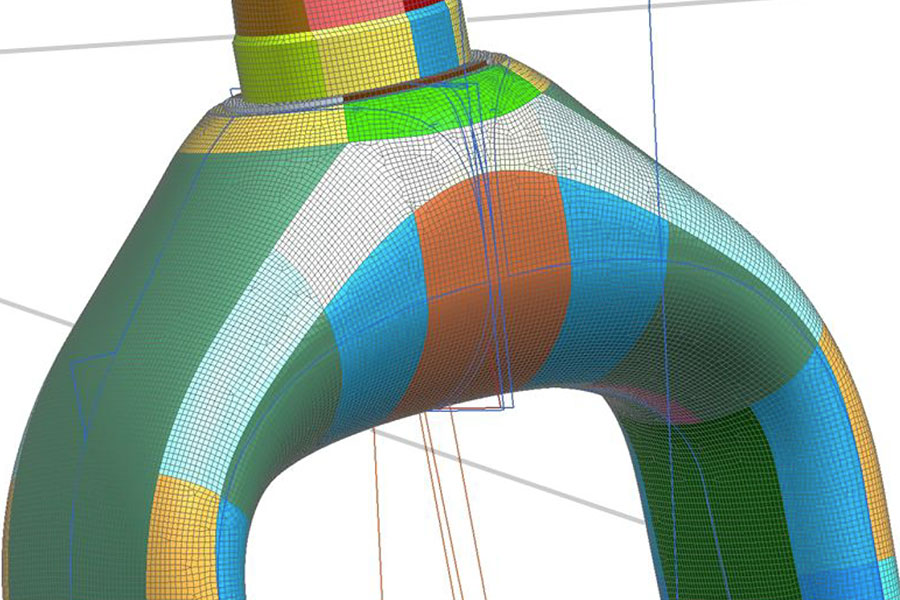

- Design Space Exploration: Evaluation of the existing components and technical requirements as well as the possible material/geometry combinations.

- Structural Design and Dimensioning in Detail: Design of structurally loaded complex components using FEM as well as sensible materials and process selection.

- Design Finalization and Prototype Production: Development of a cost- and time-efficient prototype strategy, including production planning and monitoring of prototype production.

Thanks to the cooperation with Positrigo and a huge team effort, the fast improvement, finalization and prototype production was made possible.

Image copyright of werbelinie.ch

Image copyright of werbelinie.ch Radiate Engineering & Design GmbH

Radiate Engineering & Design GmbH

Cmas Lab

Cmas Lab