Mattis Stolze from Radiate Engineering is giving a talk about “Advanced Prototyping” on November 18th as part of the Lean Startup Zürich group.

The Lean Startup Zürich Meetup group is a community who is passionate about sharing knowledge on the application of lean methodologies in start up and existing companies, big and small including and beyond software and web development.

The event takes place at Liip, Limmatstrasse 183 in Zurich and starts around 6:30 pm.

ABSTRACT “Advanced Prototyping”

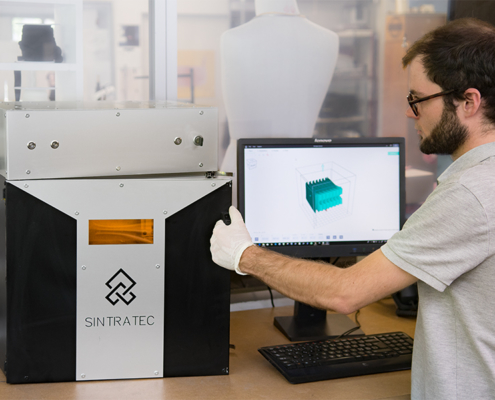

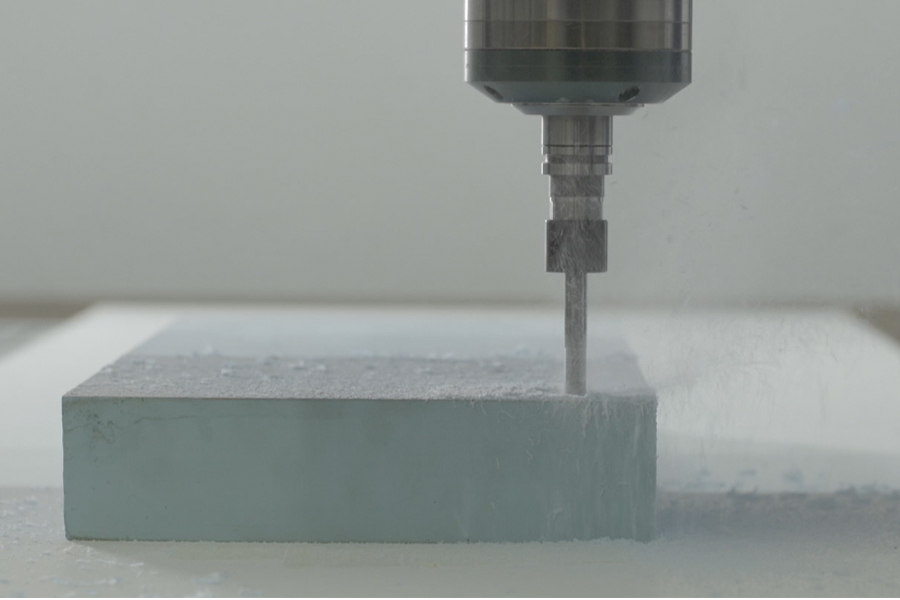

The talk focuses on Prototypes are essential for communicating ideas, testing hypotheses, and designing products. Prototypes tackle simple or complex problems, make use of paper and cardboard, 3d printing and cnc milling. There is no limit. This talk will dive into more advanced means, that enable us to invest crucial functions and hypotheses, decisive for a success of the envisioned product. By looking at real world cases, digital and analog means are examined. We take a look at pretending prototypes, cad models and mechanical prototypes, which all share a relative simplicity, low costs and a high learning potential for quick learnings.

SPEAKER: Mattis Stolze

Mattis works as consultant and development engineer at Radiate Engineering. He combines design thinking and mechanical engineering, tackles real world problems and mentors students at ETH Zurich.

AGENDA

6:30 pm Doors open & networking

6:45 pm Introduction to the Lean Startup Framework

7:00 pm Presentation followed by discussions

8:30 pm Networking

10:00 pm Closing

Radiate Engineering & Design GmbH

Radiate Engineering & Design GmbH