Jan Schenker and Gleb Kopylov join the Radiate team

Radiate Engineering & Design is happy to welcome two new team members!

First up is Mr. Jan Schenker, a talented CFD Simulation Engineer with a lot of experience in the aerodynamics at the highest level of motorsport, the Formula 1. There, he learned to push the boundaries of technology to maximize the performance. A lesson he will put to good use for the ambitious projects waiting for him at Radiate.

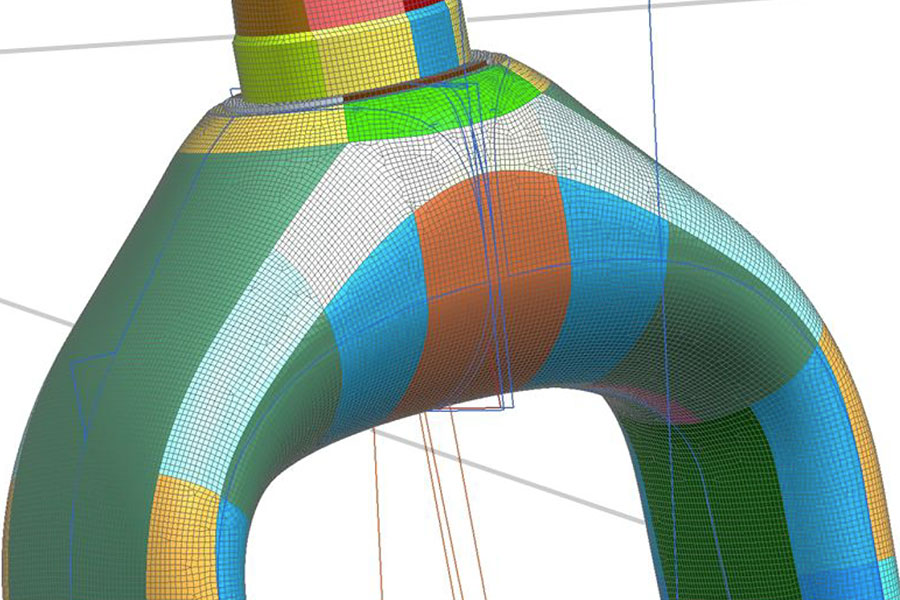

Secondly – and also with a background in the automobile sector – Mr. Gleb Kopylov joins Radiate as a Mechanical Engineer. Gleb honed his skills of CAD and FEA by designing and improving components for light sport aircrafts at CSA and by developing strength and failure analyses of elevator components at Schindler. He also worked as a System Engineer at Volkswagen Slovakia.

In their free time, both Jan and Gleb like to ride their bikes and spend time in the outdoors – needless to say, both activities go very well with the Radiate team.

Radiate welcomes the two new members and wishes them well with their efforts.

Radiate Engineering & Design GmbH

Radiate Engineering & Design GmbH Rigi Technologies AG

Rigi Technologies AG

MTB Cycletech

MTB Cycletech © Orthotec AG

© Orthotec AG